3D printed capsule with magnets too

Researchers say they have produced a bio-ink that has been specifically formulated to 3D print directly in the body, enabling doctors to deliver the right cells and materials directly to the defective part.

“This bio-ink formulation is 3D printable at physiological temperature, and can be cross-linked safely using visible light inside the body.” noted first author Ali Asghari Adib, Ph.D, in a recent press statement.

The discovery is the result of a collaboration between Ali Khademhosseini, Ph.D., Director and CEO of the Terasaki Institute, David J Hoelzle, Ph.D., from the Ohio State University Department of Mechanical and Aerospace Engineering and Amir Sheikhi, Ph.D. from the Pennsylvania State University Department of Chemical Engineering.

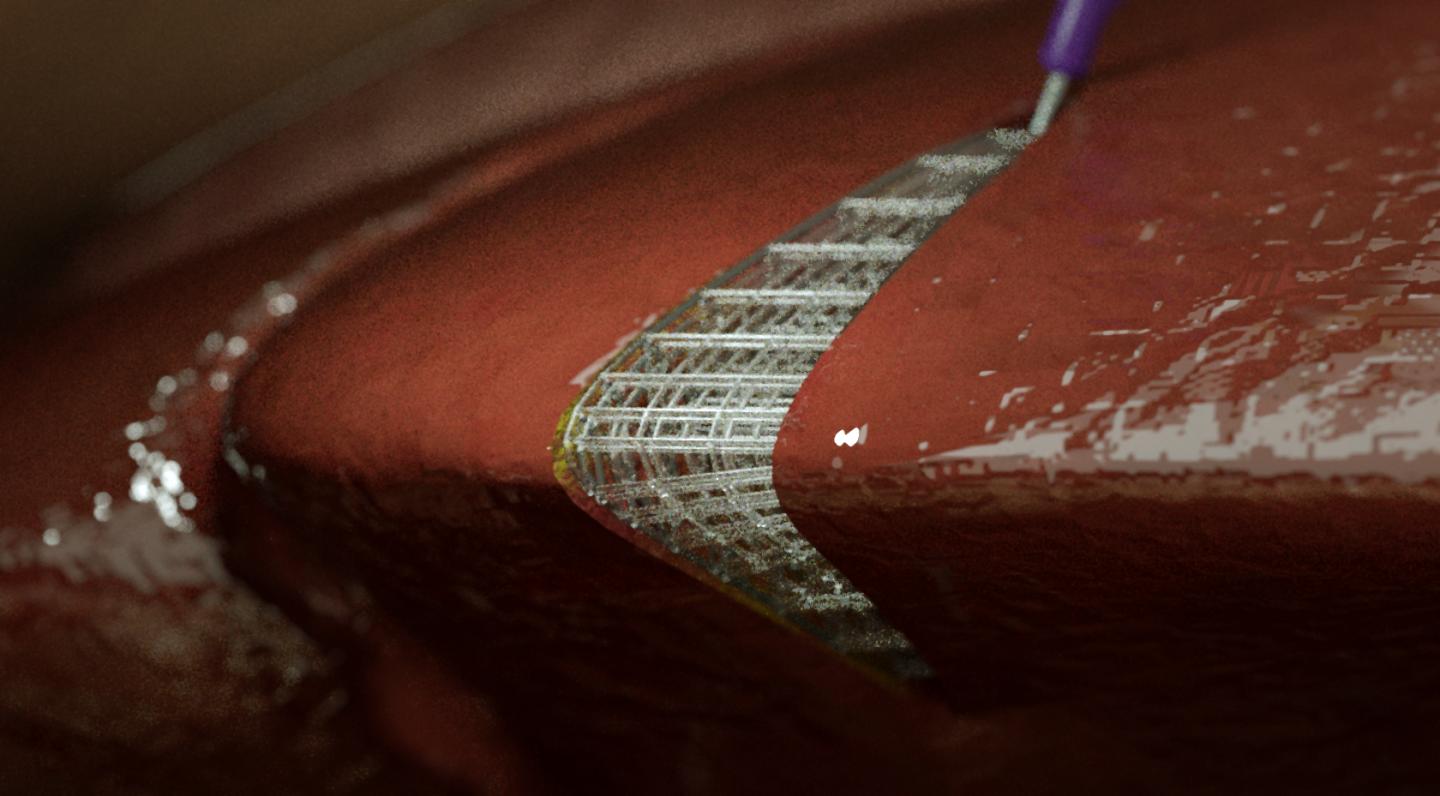

The team used robotic 3D printing–robotic machinery with a nozzle attached to it. The latter can be used to dispense the bio-ink in a more precise manner.

The process

The bioprinting process involves using a solution of a biomaterial or a mixture of several biomaterials in the hydrogel form that typically encapsulate the desired cell types–termed the bioink–to create tissue constructs, according to the National Center for Biotechnology Information.

According to the press statement, the team used a “unique interlock technique” for the robotic 3D printer and their specially-formulated bio-ink. They also modified the nozzle tip to penetrate the soft surfaces.

“The interlocking mechanism enables stronger attachments of the scaffolds to the soft tissue substrate inside the patient body,” said Asghari Adib.

“Developing personalized tissues that can address various injuries and ailments is very important for the future of medicine. The work presented here addresses an important challenge in making these tissues, as it enables us to deliver the right cells and materials directly to the defect in the operating room,” said Khademhosseini.

The researchers point out that 3D printing is being used to produce parts of the body such as orthopedic joints and prosthetics including portions of bone, skin and blood vessels.

They added, though, that the majority of these tissues are created in an apparatus outside of the body and surgically implanted, which could lead to infections and delay recovery. The research can be accessed here.

3D printed capsule with magnets too

In a related development, researchers have used 3D printing and magnetic actuation (using magnetic fields to produce and sense motion) to demonstrate that doctors may soon administer treatments with just a 3D printed capsule that is controlled by magnetic fields.

The researchers are engineers and pharmaceutical scientists, from the University of Sussex and The University of Texas at Austin.

Professor Ali Nokhodchi, head of Pharmaceutics Research Lab at the University of Sussex School of Life Sciences, and corresponding author of the article, said: “The device delivers enhanced efficacy and safety through optimal drug distribution and absorption in the targeted location at the (sub)cellular level.”

“This device has the potential to be used in treatments for cancer, diabetes, pain, and myocardial infarction which require variable release kinetics where patients’ suffer from discomfort or inconvenience if they currently rely on untunable monotonic drug treatment.”

However, the research, is in its initial phases, according to a press statement.

The study will be published in the August edition of Colloids and Surfaces B: Biointerfaces.